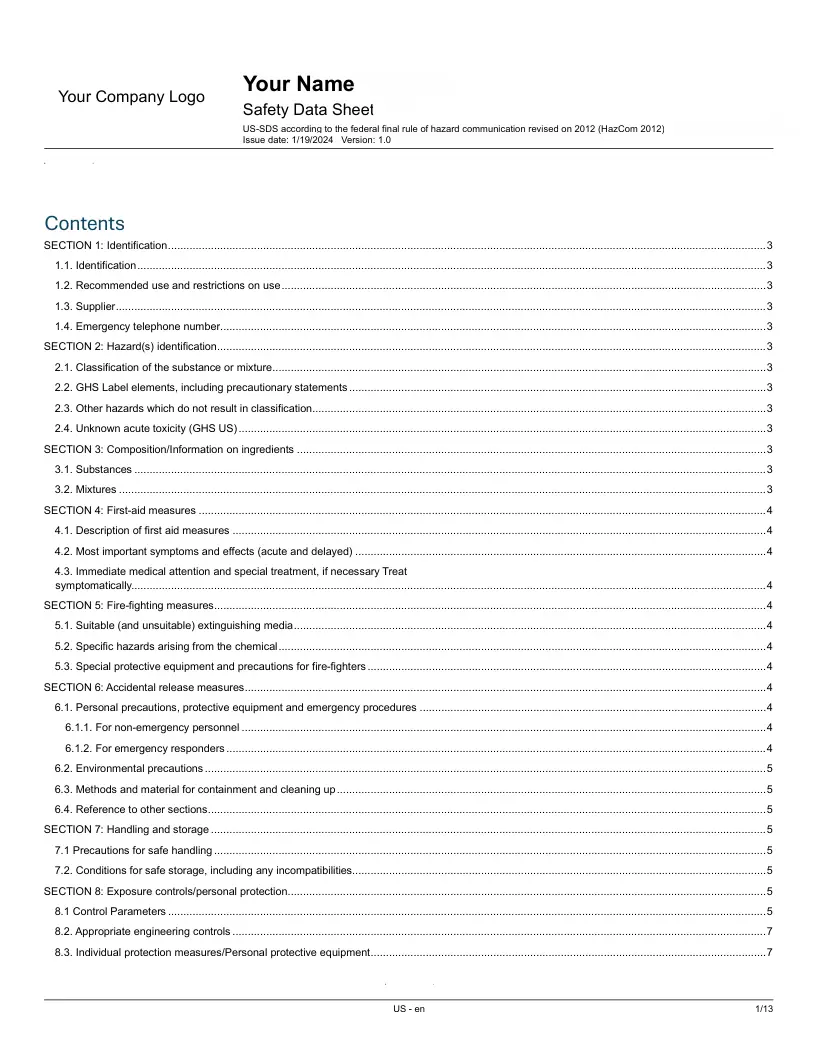

Confused between SDS and MSDS? Learn the key differences, regulatory updates, and why switching to SDS is essential for compliance in 2025. Trusted by ICSDS experts. Table of Contents Introduction In the world of chemical safety, acronyms like MSDS and SDS are often used interchangeably. But are they really the same? If you’re still referring to your safety documentation as an MSDS, you might be behind the curve — and even non-compliant. Let’s break down the difference between SDS and MSDS, understand why the transition happened, and explore how staying updated can protect your business from regulatory risks. What is MSDS? Material Safety Data Sheets (MSDS) were the traditional documents used to communicate information about chemical products — including handling procedures, hazards, and emergency measures. These sheets were common before 2012 and often varied in format and information, depending on the manufacturer or country. What is SDS? Safety Data Sheets (SDS) replaced MSDS as part of the Globally Harmonized System (GHS) introduced by OSHA and international bodies. Unlike MSDS, the SDS follows a standardized 16-section format, ensuring clarity, consistency, and global compliance. This format makes it easier for employees, emergency responders, and regulators to find the information they need quickly. Key Differences Between SDS and MSDS Feature MSDS SDS (Post-GHS) Format Non-standard, varies Standardized 16-section format Global Harmonization No Yes (GHS-compliant) Language Technical, inconsistent Clear, consistent terminology Regulatory Approval May not meet updated regulations Required for OSHA, WHMIS, REACH Usage Year Pre-2012 Post-2012 (mandatory) Why the Change Was Necessary The shift from MSDS to SDS was driven by the need for global standardization and clear communication. Different formats led to confusion and safety risks. The GHS introduced SDS to: Improve understanding of hazards Simplify training and compliance Enhance international trade and worker protection Who Needs to Comply with SDS? Any business that manufactures, imports, distributes, or uses chemicals is required to maintain updated SDS documentation. This includes: Chemical manufacturers Cleaning product companies Laboratories Construction firms E-commerce sellers of chemical-based goods SDS Compliance in 2025 With ongoing updates in OSHA and WHMIS regulations, non-compliance can result in penalties, product recalls, or reputational damage. As we step into 2025, businesses must ensure: SDS documents are current and GHS-compliant Records are accessible and properly organized Staff are trained on SDS interpretation and emergency measures How ICSDS Can Help At ICSDS, we specialize in authoring, reviewing, and managing SDS documentation for businesses across the USA and Canada. Our experts ensure: ✅ Full GHS compliance✅ Industry-specific customization✅ Quick turnaround time✅ Affordable and scalable SDS solutions Whether you’re updating legacy MSDS files or creating SDS from scratch, ICSDS is your trusted partner in compliance and chemical safety. Final Thoughts The terms SDS and MSDS might sound similar, but the differences are critical. Transitioning to SDS isn’t just a regulatory checkbox — it’s a step toward better safety, global trade readiness, and employee protection. Make sure your documentation reflects today’s standards. Don’t let outdated MSDS files put your business at risk. Ready to upgrade your MSDS to fully-compliant SDS documentation? 👉 Contact ICSDS today for a free consultation and get expert support tailored to your industry. Stay compliant. Stay safe. Stay ahead. Click Here