The Importance of MSDS/SDS Compliance: Why Businesses Trust ICSDS LLC

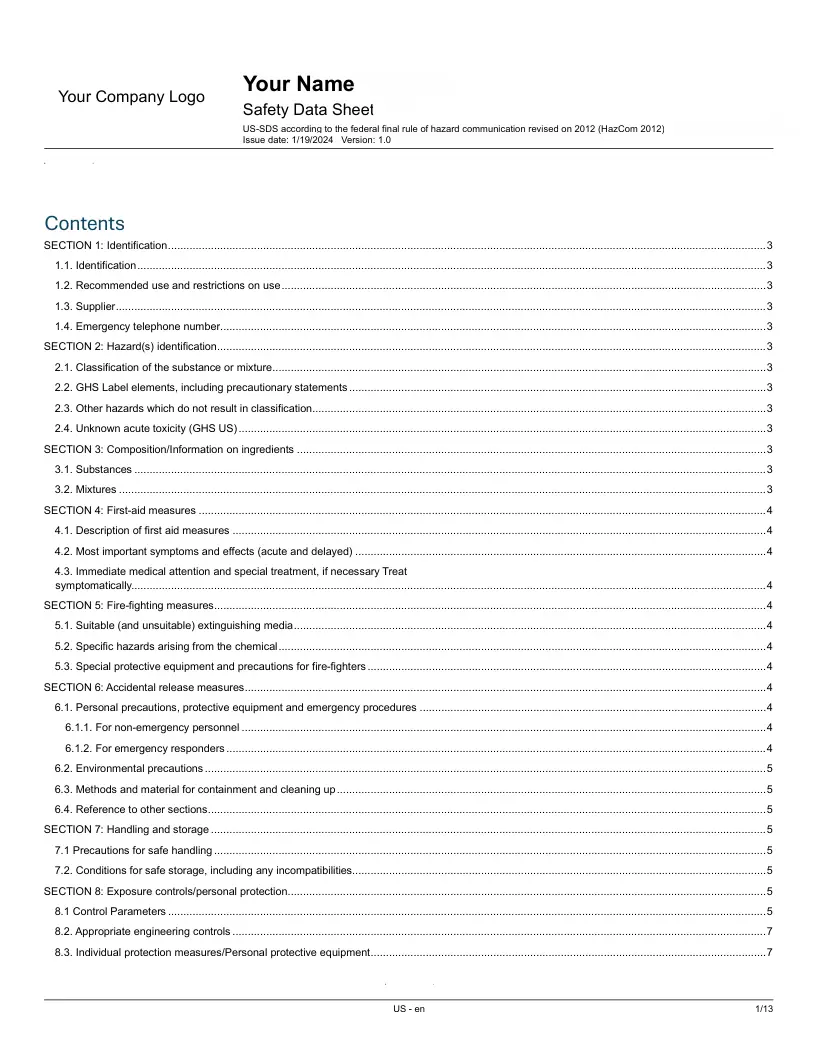

Looking for reliable MSDS/SDS services? ICSDS LLC offers expert Safety Data Sheet authoring, conversion, and compliance solutions for businesses across the USA and Canada. Contact us at icsds@icsds.com to stay compliant and safe. Introduction to MSDS/SDS Material Safety Data Sheets (MSDS) and Safety Data Sheets (SDS) are critical documents used to communicate the properties of chemical products. Whether you’re manufacturing, distributing, or using chemicals, maintaining accurate and up-to-date MSDS/SDS documentation is a legal and safety requirement. With ever-evolving regulations like OSHA’s Hazard Communication Standard (HCS) and the Globally Harmonized System (GHS), businesses must ensure their safety documents meet compliance requirements. Why MSDS/SDS Compliance Matters Failing to comply with MSDS/SDS regulations can lead to: SDS documents serve as the first line of defense in workplace chemical safety, protecting workers and ensuring that emergency responders are well-informed in case of incidents. ICSDS LLC: Your Trusted Partner in MSDS/SDS Services At ICSDS LLC, we specialize in Safety Data Sheet authoring, GHS conversion, and MSDS to SDS updates for businesses across North America. Our experts ensure your chemical documentation complies with the latest global and local regulatory standards. 📧 Reach out to us: icsds@icsds.com Key MSDS/SDS Services Offered by ICSDS LLC We provide a full range of MSDS/SDS services, including: Every SDS we create is GHS-aligned, OSHA-compliant, and ready for international use. Industries We Serve ICSDS LLC proudly supports clients in industries such as: Whether you’re a small chemical distributor or a multinational manufacturer, we tailor our SDS solutions to fit your needs. Why Choose ICSDS LLC for Your SDS Needs ✅ Experience You Can Trust: Over a decade of experience in MSDS/SDS services✅ Regulatory Accuracy: Up-to-date with OSHA, GHS, WHMIS, REACH & more✅ Affordable Solutions: Cost-effective pricing without compromising quality✅ Confidentiality Guaranteed: Your formulas and data are 100% secure✅ USA & Canada Focus: Experts in North American compliance standards ICSDS LLC is not just a service provider—we are your compliance partner. Get Started Today with ICSDS LLC Don’t leave your MSDS/SDS compliance to chance. Partner with ICSDS LLC to ensure safety, legal compliance, and peace of mind. 📧 Contact Us TodayEmail: icsds@icsds.comWebsite: www.icsds.com