The Role of SDS in OSHA and WHMIS Compliance

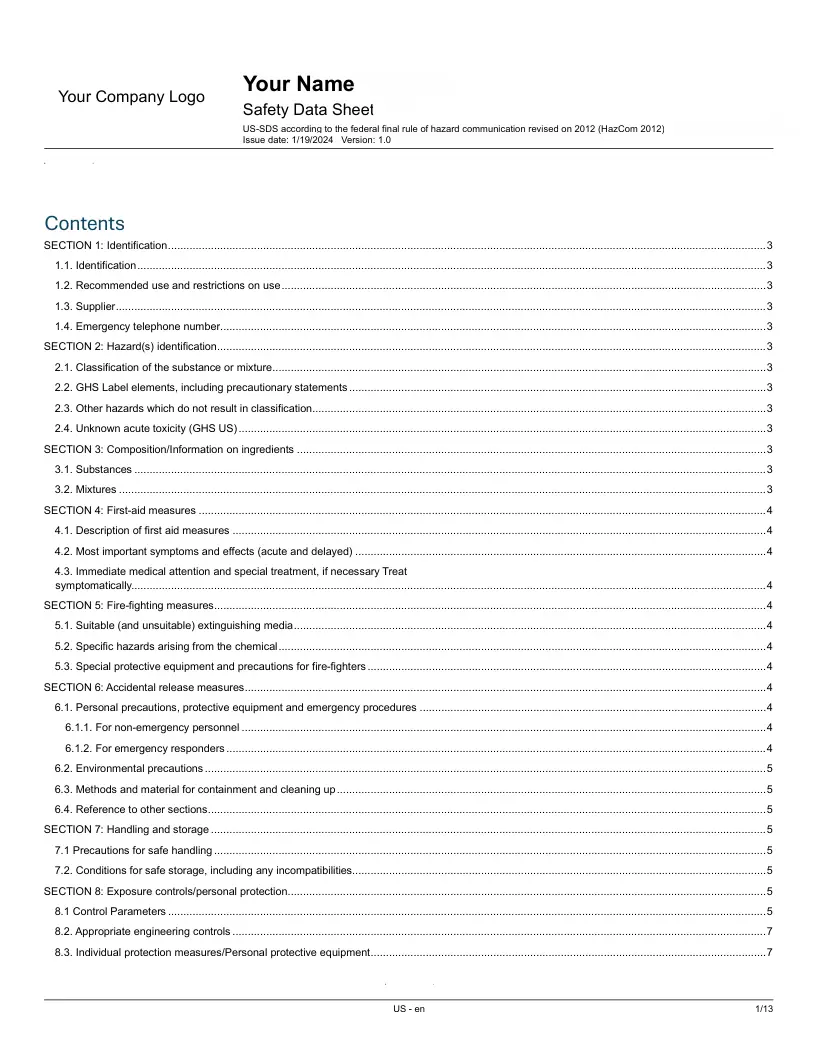

Learn how Safety Data Sheets (SDS) play a critical role in OSHA and WHMIS compliance. Discover key differences, shared principles, and best practices for regulatory success. Table of Contents Introduction Safety Data Sheets (SDS) are the backbone of workplace safety regulations in the USA and Canada. These documents ensure that employees and employers have access to critical information about hazardous materials, enabling safer handling and storage. SDS also serve as a key component in compliance with OSHA (Occupational Safety and Health Administration) and WHMIS (Workplace Hazardous Materials Information System). This blog dives into how SDS support these regulatory frameworks, their shared principles under the Globally Harmonized System (GHS), and why they are vital for cross-border compliance. What Is OSHA Compliance? OSHA, the United States’ workplace safety watchdog, sets the standards for protecting employees from chemical hazards. One of its most critical regulations is the Hazard Communication Standard (HCS), which mandates that manufacturers, importers, and distributors provide accurate SDS for hazardous products. SDS ensures that employees are informed about: Failing to comply with OSHA’s SDS requirements can result in steep fines and jeopardize workplace safety. Understanding WHMIS In Canada, WHMIS governs the communication of hazardous materials in workplaces. It mandates that all hazardous products come with an accurate SDS to inform workers about potential risks and safety measures. Key components of WHMIS include: By providing comprehensive information, WHMIS empowers employees to minimize risks and respond effectively to emergencies. The SDS as a Bridge Between OSHA and WHMIS Both OSHA and WHMIS are grounded in the principles of the Globally Harmonized System (GHS). This ensures a standardized approach to chemical classification and labeling, making SDS consistent across borders. For businesses operating in both the USA and Canada, a GHS-compliant SDS simplifies compliance with OSHA and WHMIS regulations, reducing duplication and ensuring uniform safety practices. Key Differences Between OSHA and WHMIS While OSHA and WHMIS share common principles, there are notable differences: Understanding these differences is critical for businesses operating internationally. Why Accurate and Up-to-Date SDS Matter Non-compliance with OSHA or WHMIS can lead to: To stay compliant, businesses must: Leveraging Digital Tools for Compliance Digital SDS management systems streamline the compliance process by: Choosing the right tool ensures that your business stays compliant and reduces administrative burdens. Conclusion Safety Data Sheets are more than regulatory paperwork; they are a critical element of workplace safety. By ensuring OSHA and WHMIS compliance, businesses protect employees, avoid legal risks, and build trust with customers. Take the next step to simplify your compliance journey with ICSDS—explore digital SDS management solutions tailored to your needs.