The 16 Sections of an SDS: Breaking Down the Essentials

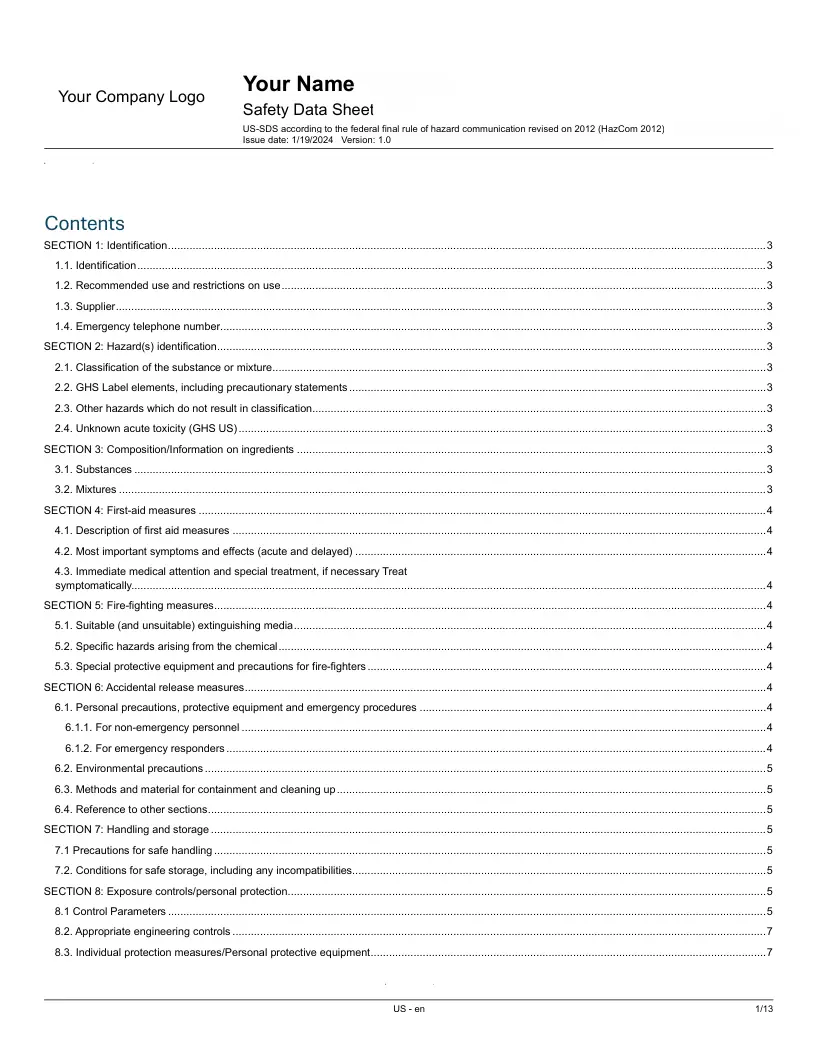

Learn about the 16 sections of a Safety Data Sheet (SDS) and their importance in ensuring workplace safety and regulatory compliance. A must-read for businesses handling chemicals. Table of Contents Introduction Safety Data Sheets (SDS) play a vital role in workplace safety and chemical management. These standardized documents provide essential information about hazardous substances, helping employers and employees understand the risks and safety measures associated with handling chemicals. This blog will break down the 16 sections of an SDS, making it easy to understand their significance and purpose. What is a Safety Data Sheet (SDS)? An SDS is a detailed document that provides critical information about a chemical substance or mixture. It ensures compliance with regulations such as OSHA‘s Hazard Communication Standard (HCS) in the US and WHMIS 2015 in Canada. An SDS is essential for businesses to maintain safety and regulatory compliance. The Importance of SDS Compliance Compliance with SDS requirements is not just about avoiding fines; it’s about protecting workers, the environment, and your business reputation. Properly formatted and accurate SDSs ensure that employees have the knowledge to handle chemicals safely, reducing the risk of accidents and exposure. Breaking Down the 16 Sections of an SDS Let’s explore the 16 sections of an SDS, as mandated by the Globally Harmonized System (GHS): Section 1: Identification Section 2: Hazard(s) Identification Section 3: Composition/Information on Ingredients Section 4: First-Aid Measures Section 5: Fire-Fighting Measures Section 6: Accidental Release Measures Section 7: Handling and Storage Section 8: Exposure Controls/Personal Protection Section 9: Physical and Chemical Properties Section 10: Stability and Reactivity Section 11: Toxicological Information Section 12: Ecological Information Section 13: Disposal Considerations Section 14: Transport Information Section 15: Regulatory Information Section 16: Other Information Conclusion Understanding the 16 sections of an SDS is essential for ensuring workplace safety and regulatory compliance. Each section provides valuable information that helps protect employees, the environment, and the business itself. If you’re looking for expert guidance or professional SDS authoring services, ICSDS is here to help. With our expertise in compliance for the US and Canada, we ensure your SDSs are accurate, up-to-date, and aligned with industry standards. Contact ICSDS today to simplify your SDS compliance journey!